A holistic energy concept for the future: How Staehle saves 85% heating energy with ENGIE

ENGIE Deutschland has been putting energy efficiency into practice for 30 years - with the Energy Performance Contracting (ESC) model. What began in 1994 with the first projects is now an integral part of our strategy for a carbon-neutral future.

The results speak for themselves:

- 550,000 tons of CO₂ saved

- 200 million euros in reduced energy costs

- 80 experts working daily on smart solutions

A current example that shows how the model also works for medium-sized industrial companies is the project with the Swabian company Staehle.

Staehle: Sustainability as a corporate principle

Staehle GmbH & Co KG is a leading German specialist for aerosol packaging - and consistently focuses on quality, safety and sustainability. At its production site in Schifferstadt, Rhineland-Palatinate, the Swabian family business manufactures high-quality aerosol cans for a wide range of applications in three-shift operation. High demands are placed on process stability, security of supply, and energy efficiency.

That is why the company chose a new approach to energy efficiency – in partnership with ENGIE Deutschland GmbH.

„At Staehle, we are committed to protecting the environment, because sustainability plays a major role in our company," explains Marc Oliver Staehle, Managing Director. "We want to use the best possible technology to continuously improve our energy efficiency. With ENGIE Deutschland, we now have the right, competent partner on board for this in Schifferstadt.“

With the holistic energy concept implemented at the site, Staehle is consistently pursuing this goal - and proving that climate protection, cost-effectiveness, and production security are by no means mutually exclusive.

The Staehle project: From challenge to holistic energy concept

An outdated heating system, new legal requirements - and the willingness to not only react, but to fundamentally rethink its own energy supply: Together with ENGIE, Staehle developed a comprehensive, future-oriented energy concept for its production site.

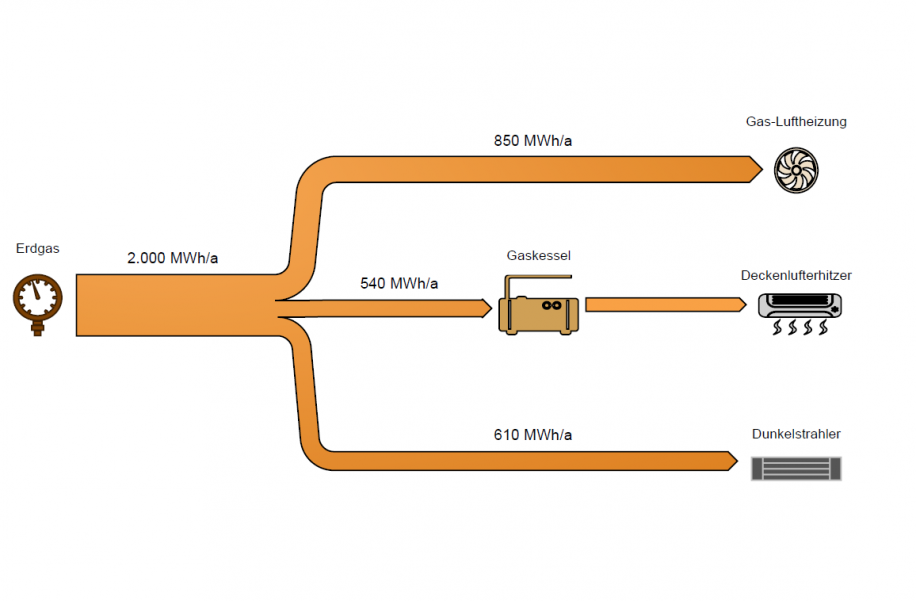

The starting point was the replacement of an outdated, gas-fired air heating system that could no longer be operated. Rather than settling for a single solution, Staehle and ENGIE opted for an integrated, holistic approach: the entire heat and energy supply was redesigned - ecologically, efficiently, and economically.

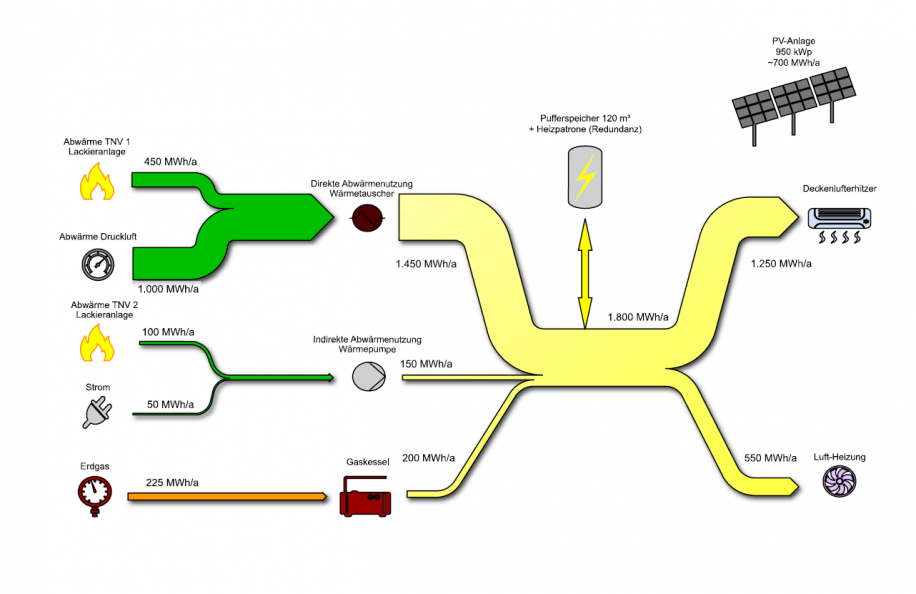

The technical concept includes:

- Waste heat recovery from the paint shop and compressed air supply

- a PV system with an output of just under 1 MWp

- a powerful heat pump

- an intelligent storage and control system with buffer storage tanks (6 x 20 m³), which store heat for use during production-free weekends

The result is convincing across the board:

- Up to 85 % renewable heat generation

- Reduction in gas consumption by around 85% - from 2 million kWh to 300,000 kWh per year

- over 300,000 euros in annual energy cost savings

- More comfort for employees - thanks to a new heating and cooling system

Staehle has also consistently taken a holistic approach in economic terms: it relies on the proven ESC model from ENGIE - and also benefits from an expected subsidy of around 350,000 euros as part of the BAFA Module 4 programme - energy and resource-related optimization of systems and processes, including a decarbonization bonus.

The special feature: As this is a contracting project, ENGIE not only takes on the planning, construction and operation of the system, but also the application for subsidies. This minimizes the effort for the customer - and makes optimum use of the funding potential.

Before and after in comparison - the new energy concept at a glance

We spoke to Daniel Münch. He is Head of Energy Efficiency Sales at the Stuttgart branch and is responsible for the project at ENGIE Deutschland.

How did the project start?

Daniel Münch: "The customer had an acute need for action - an outdated gas-fired air heating system could no longer be operated. That was the starting point. We used this challenge to develop a holistic concept for the entire site."

What distinguishes this project from traditional energy-saving measures?

Daniel Münch: "The difference lies in the depth and networking: we combine the waste heat from production with a large PV system, a heat pump and a buffer storage system. This creates a holistic energy concept that is both ecologically and economically convincing."

How was this financed?

Daniel Münch: "Staehle contributed its own funds, the rest is refinanced via our energy-saving contracting. As it is a contracting model, we have also applied for funding from BAFA Module 4. With the decarbonization bonus, we expect to receive around € 350,000 in funding. That makes the project even more attractive."

What is special about this project for you?

Daniel Münch: "That it can serve as a blueprint - for many other SMEs. It shows: Comprehensive solutions can also be implemented with manageable effort. The prerequisite is a partner who thinks about technology, financing and implementation together - in other words, holistically."

Energy-saving contracting as the basis for a holistic energy concept

The Staehle project is an example of what 30 years of energy-saving contracting with ENGIE means: practical, well thought-out solutions that turn challenges into viable concepts for the future - with measurable results for the carbon footprint, operating costs and security of supply.

With ESC, ENGIE assumes full responsibility for energy-saving measures - from planning and financing to implementation and operation. Customers benefit from:

- lasting savings in energy and operating costs

- Guaranteed success during the term of the contract, otherwise ENGIE will make a compensation payment

- lower CO2 emissions as a contribution to climate protection

- more time and budget for your core business

- new and low-maintenance system technology without own capital expenditure

Integrated energy concepts in particular, such as Staehle's, can be implemented economically and sustainably via ESC - and are additionally supported by funding programs such as BAFA Module 4. ENGIE not only contributes technical expertise, but also the necessary understanding of the regulatory framework and funding logic - an often decisive success factor for SMEs that want to future-proof their energy system.

Our Expert