Air Protect Cluster by ENGIE

Safe ventilation of wastewater systems in high-security areas of protection and safety levels 3 and 4

Proper aeration and deaeration of wastewater systems is relevant to safety to ensure that no infectious airborne biological agents are released through the wastewater vent lines. Research centers, microbiology or genetic engineering laboratories, isolations wards or animal husbandry facilities share high protection and safety levels 3 and 4. The legal regulations can be found in the Biological Substances Ordinance and the Genetic Engineering Safety Ordinance which assert infectious biological agents may not be released into the environment without first being inactivated and decontaminated.

Safe, low-maintenance & energy-efficient

ENGIE's Air Protect Cluster* is the innovative treatment solution for exhaust air of wastewater discharging systems in high-security areas of protection and safety levels 3 and 4. State of the art, it meets all legal requirements and complies with the technical regulations. At the same time, the Air-Protect Cluster offers high energy-efficiency and low operating costs. The high maintenance costs of residue blocked conventional HEPA filter solutions are eliminated.

-

Secure

Fulfills the legal requirements such as GenTSV and BioStoffV -

Efficient

Low operating costs and high energy-efficiency -

Low maintenance

No saturation means no blocking of the HEPA filter -

Tried and tested

The Air Protect Cluster already successfully operating in several laboratories and animal husbandry facilities -

Flexible

Upgrades to the Air Protect Cluster for existing HEPA filter systems are also possible

Developed through experience and practice

We have developed the Air Protect Cluster on the basis of our many years of experience with technical systems in high-security laboratories together with leading institutes, engineering and scientific consultants of MLT Medical and Laboratory Technology, and our filter partner Camfil. Our goal was to be able to offer a safe solution, the effectiveness of which can be proven by measurement and. at the same time energy efficient to achieve low operating costs. Any maintenance and disturbance in high-security areas involves high costs and expenditure.

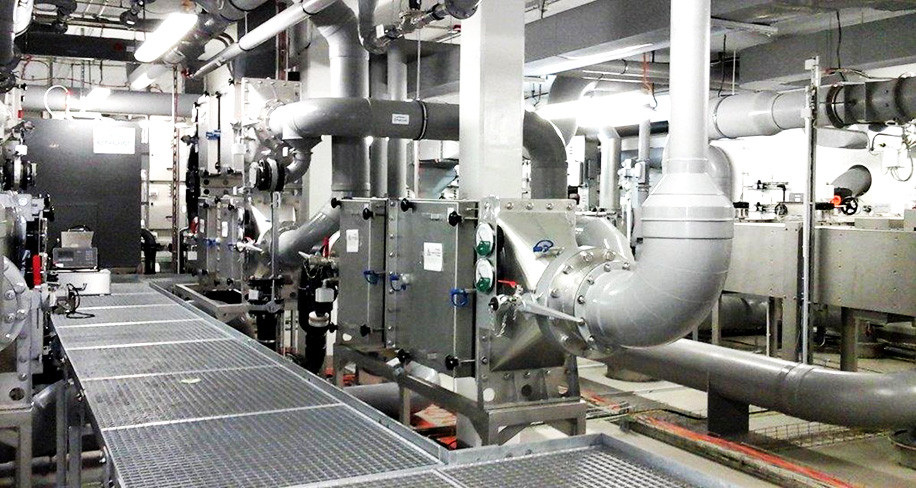

With the Air Protect Cluster, we have found a solution that meets all these criteria and ensures reliable and proper ventilation of the entire wastewater system. Our innovative solution is already being used in several laboratories and animal husbandry facilities. The application in practice continues to confirm the advantages of the Air Protect Cluster.

Application in practice

"Today, after commissioning the first Air Project Cluster in February 2018, FLI operates a total of six systems for the ventilation and exhaust of wastewater systems in high-security areas (stables and laboratories) of protection and security levels 3 and 4. As part of the functional verification of the filter systems, the HEPA filters were subjected to an annual leakage and seal leakage test in accordance with EN 1822-1. The integrated filter systems Cam Contain (Camfil KG) offer the user the prerequisites for in situ scanning testing and decontamination of the HEPA filter stages. For all HEPA filter elements, the filtration performance (filter class H14) could be demonstrated in repeated tests.

The use of the Air Protect Cluster prevents permanent moisture penetration of the filter medium and thus stops the gradual blocking of the filter clusters. In the application, the systems also offer interfaces for setpoint specifications and corrections of system pressures in the wastewater network. This innovative solution eliminates the risk of exposure to biomaterials during the operation of wastewater systems."

Rene Stenzel, Technical Service

Friedrich Löffler Institut Isle of Riems

Protection measures in comparison

The Air Protect Cluster for ventilation in high-security areas of protection and security levels 3 and 4 offers numerous advantages over conventional solutions.

|

|

HEPA filter |

Thermal coil |

Air-protect cluster |

|

Permanent ventilation of the base and down line |

- | ||

|

Underpressure operation of the air system possible |

- | ||

|

No constriction of the main line |

- | ||

|

Permanent HEPA air filtering for outside air |

- | - | |

|

No barrier-free air flow |

- | ||

|

No blocking of the protection measure |

- | ||

|

Low operating costs (energy/maintenance) |

- | ||

|

Verifiable testing of the protection measure |

- | - | |

|

Decontaminatability of system technology |

- | ||

|

Reliable filter change in compliance with the verified decontamination method |

- | - | |

|

In situ testing of HEPA filters |

- | ||

| Once a year test for the functioning of the safeguard measure sufficient* |

- | ||

|

Decontamination of the system technology using hydrogen peroxide (H2O2) |

*recommended test interval Resolution ABAS 16/2010 page 1, ELATEC project group, HEPA filter